Why it matters: When the pandemic rolled through the global economy four years ago, it became clear to US officials that they had let its domestic semiconductor manufacturing capabilities deteriorate to dangerous levels. Hence the seeds of the CHIPS and Science Act were planted. The Act was allocated a total of $52.7 billion when it was signed into law in August 2022 and it has been doling out money out ever since. The latest recipient will likely be Texas Instruments, which has plans to use the funding to enhance its footprint in high-volume 300mm wafer capacity.

In a move aimed at bolstering the US’ semiconductor manufacturing capabilities, Texas Instruments and the US Department of Commerce have signed a preliminary agreement outlining potential terms for up to $1.6 billion in proposed direct funding under the CHIPS and Science Act.

This funding would support the construction of three 300mm wafer fabrication facilities in Texas and Utah. Alongside this, TI anticipates receiving an additional $6 billion to $8 billion from the US Department of Treasury’s Investment Tax Credit, designed to incentivize qualified US manufacturing investments. Together, these financial boosts are set to help TI secure a geopolitically stable supply of essential analog and embedded processing semiconductors.

The proposed direct funding is a part of TI’s ambitious plan to invest over $18 billion through 2029 to expand its manufacturing footprint.

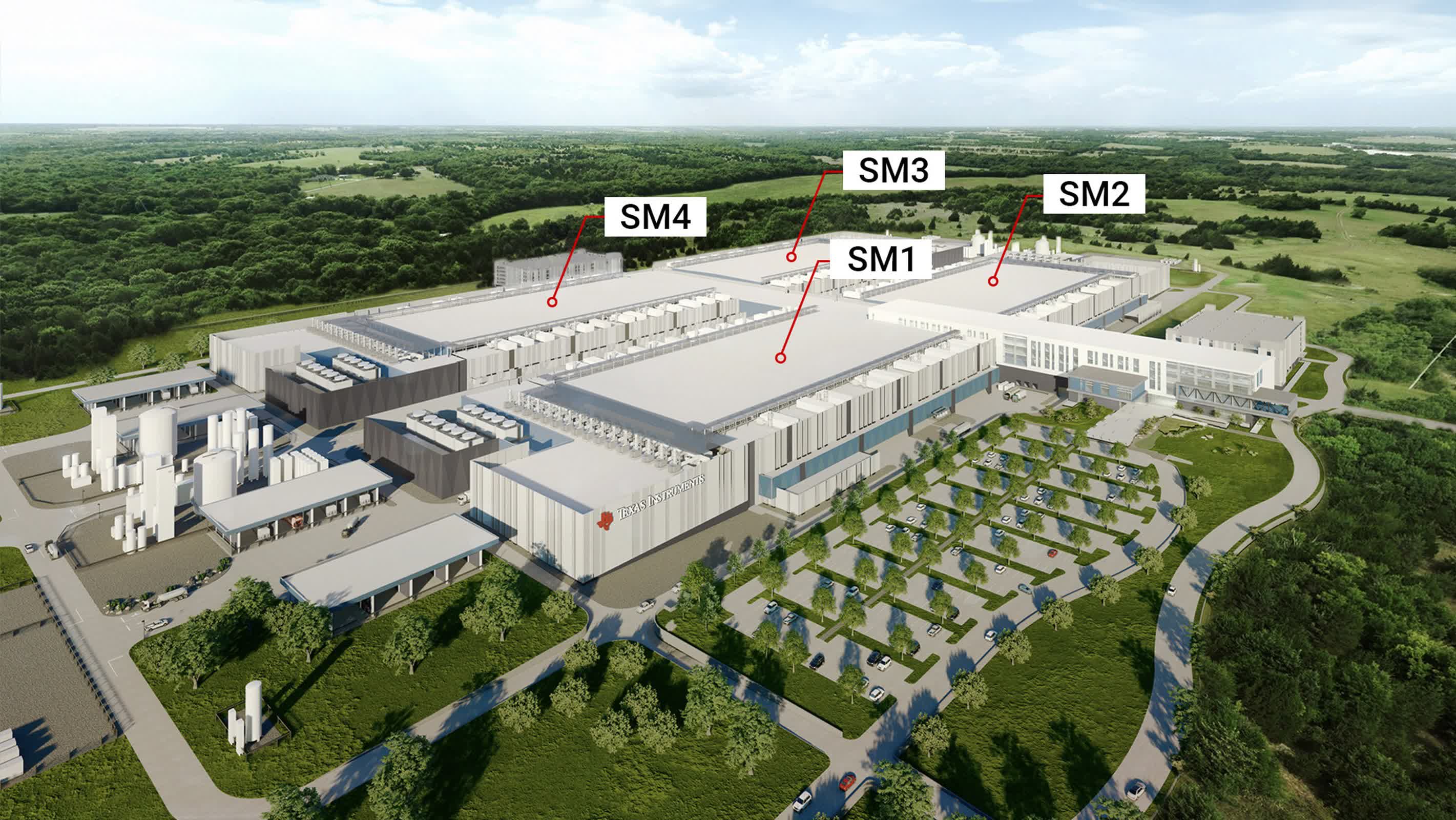

The CHIPS Act funding will be allocated to three new wafer fabs: two in Sherman, Texas, and one in Lehi, Utah. The Sherman facilities, SM1 and SM2, are poised to become major players in the semiconductor industry, producing 65nm to 130nm chips with an expected daily output exceeding one hundred million chips. Notably, the Sherman site stands out as one of the few greenfield production sites for 300mm wafer chips in the United States.

Meanwhile, the Lehi, Utah facility, LFAB2, is set to produce 28nm to 65nm analog and embedded processing chips, with an anticipated daily production of tens of millions of chips. This project marks the largest economic investment in Utah’s history.

TI is one of the few companies in the US building high-volume 300mm wafer capacity for foundational technologies. Its efforts are crucial to increasing domestic manufacturing capabilities for mature-node chips, which are essential for a wide range of applications, from consumer electronics to critical infrastructure.

The company’s investment aligns with broader national efforts to revitalize the US semiconductor industry, which has seen its share of global production decline from 37% to just 12% over the past three decades.

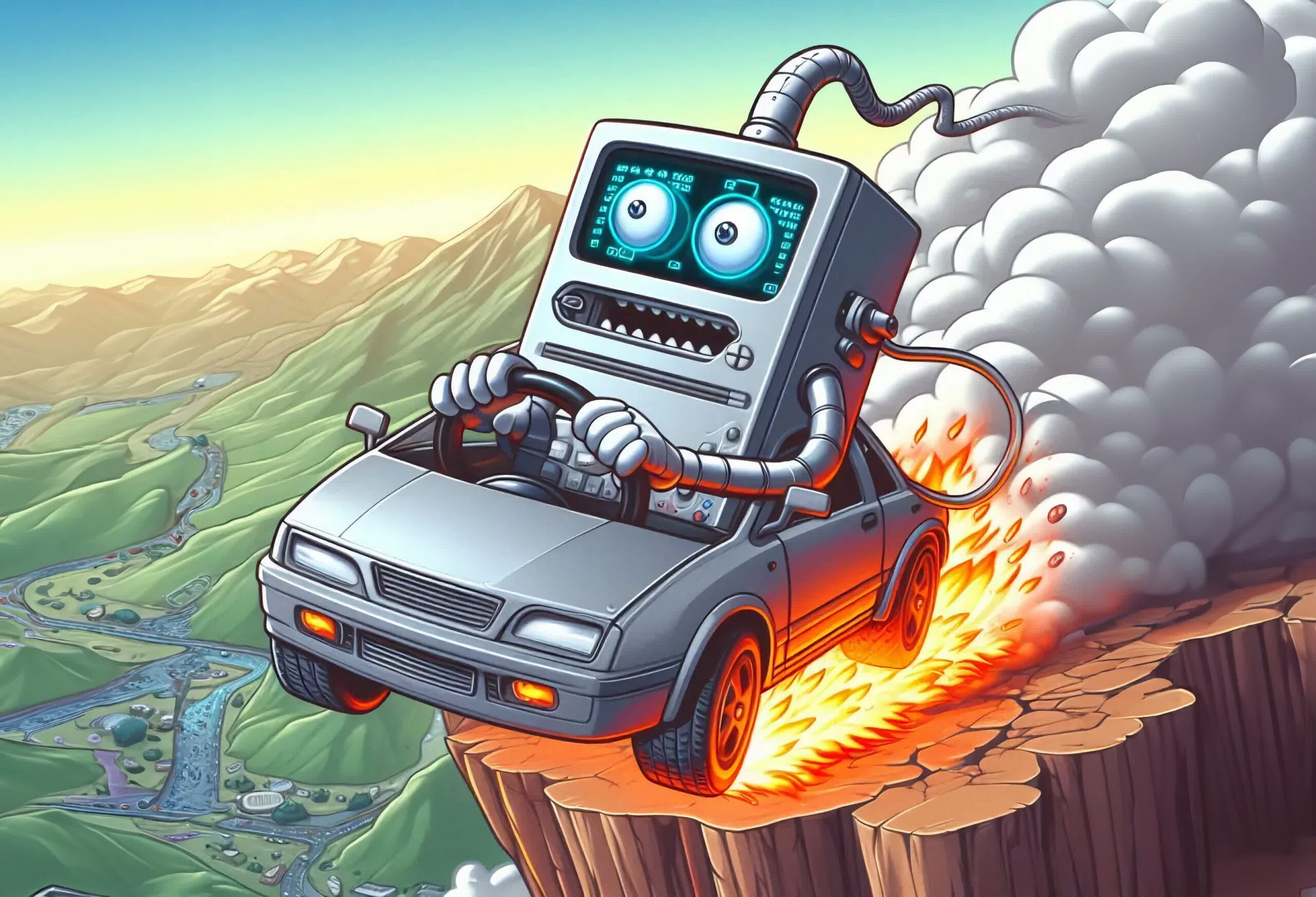

It took the COVID-19 pandemic to expose the impact of this decline with its disruption of the global semiconductor supply chain, which particularly hurt the US automotive, industrial, and defense sectors. These industries rely heavily on semiconductors for their operations, and the disruptions caused by the pandemic led to severe production slowdowns and increased costs.

For instance, the US automotive industry faced production halts and furloughs due to chip shortages, contributing to a sharp rise in vehicle prices and impacting the overall economy. The shortage was so severe that it reportedly knocked a full percentage point off the US GDP in 2021.

By focusing on building robust domestic production capabilities, TI and other industry leaders hope to build a more resilient and self-sufficient supply chain. This strategy will help avoid future disruptions and support the country’s long-term economic growth and technological progress.